Scientists Engineer Microbes to Convert Plastic Bottles into Painkillers

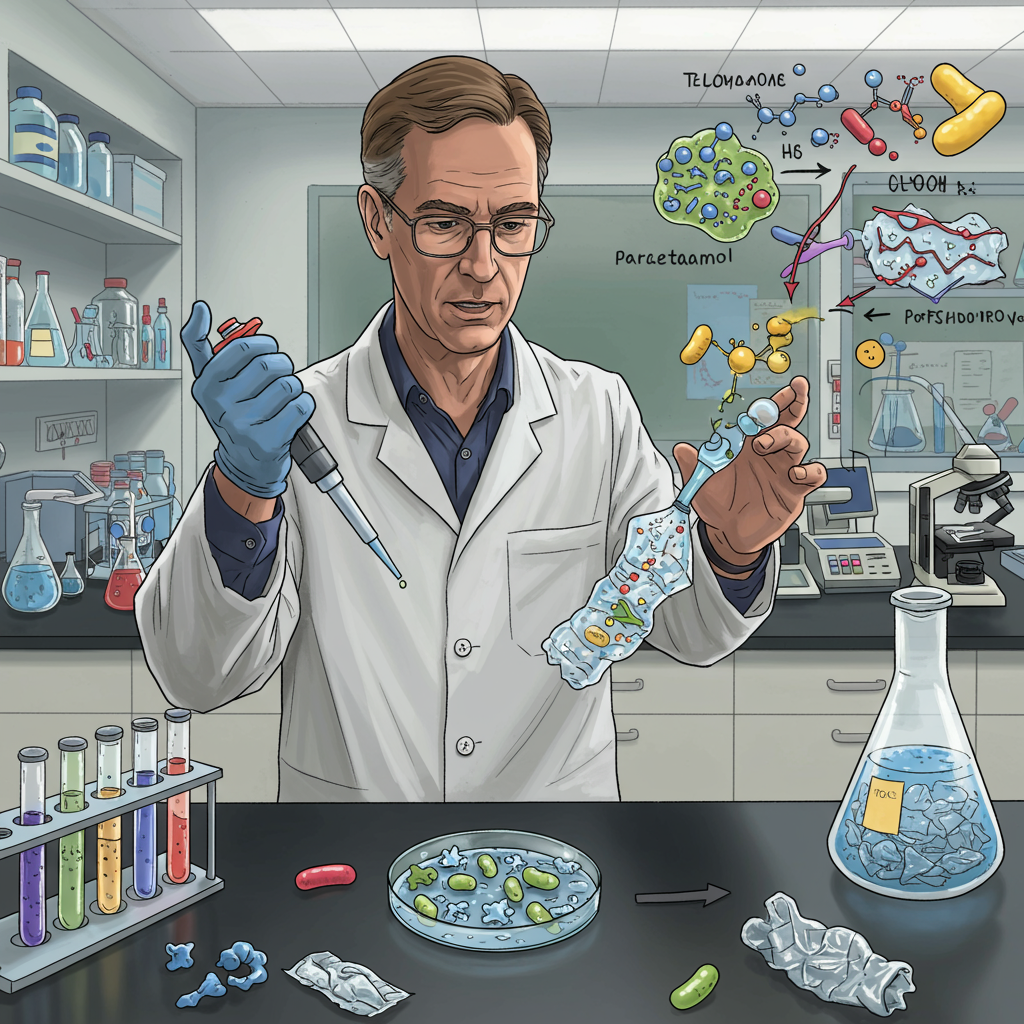

In a groundbreaking development, scientists have successfully engineered bacteria to transform plastic waste into a common medicine – paracetamol. This pioneering research, led by Professor Stephen Wallace at the University of Edinburgh, marks the first time live microbes have been used to produce pharmaceuticals from digested waste materials, opening a potential new avenue for sustainable drug manufacturing and plastic recycling.

The study, published in the journal Nature Chemistry, demonstrates a novel fusion of chemistry and synthetic biology. Instead of relying on traditional, often petroleum-based chemical processes, the team harnessed the inherent capabilities of living cells to perform complex molecular transformations.

How Bacteria Digest Plastic into Medicine

The process begins with polyethylene terephthalate (PET) plastic, the type commonly used in beverage bottles and food packaging. This waste plastic is broken down into a key component molecule, such as terephthalic acid (TA). This plastic-derived molecule then serves as the starting material fed to specially modified Escherichia coli (E. coli) bacteria.

The researchers used synthetic biology techniques to create new biological pathways within the E. coli. A crucial insight was discovering that the bacteria naturally contain phosphate, a molecule capable of facilitating a specific chemical reaction known as the Lossen rearrangement. This reaction is vital for converting acid-derived molecules from the plastic into precursors for drug production.

To guide the bacteria towards producing paracetamol, the scientists engineered the E. coli in several ways:

They modified the bacteria to disable their natural ability to produce a molecule called para-aminobenzoic acid (PABA), forcing them to utilize the plastic-derived material as their source for PABA.

They introduced two additional genes into the bacteria – one from mushrooms and another from soil bacteria. These genes equipped the E. coli with the specific enzymatic machinery needed to convert PABA directly into acetaminophen, the active ingredient in paracetamol.

Essentially, the bacteria were provided with a genetic blueprint that directed their internal chemistry to perform the necessary steps, converting plastic-derived molecules first into PABA via the phosphate-catalyzed Lossen rearrangement, and then into paracetamol using the added enzymes. This complex transformation occurred within the bacterial cells under mild, biocompatible conditions, unlike the harsh, energy-intensive conditions often required for similar reactions in traditional chemistry labs.

The engineered microbes proved remarkably efficient, converting the plastic-derived material into paracetamol with a high yield of up to 92% within a 24-hour period in laboratory settings.

A Greener Path for Pharmaceuticals and Recycling

This innovative method presents a compelling alternative to conventional paracetamol production. Currently, the vast majority of paracetamol is synthesized from petroleum derivatives, a process that is energy-intensive and generates significant carbon emissions.

In stark contrast, the bacterial conversion process operates at room temperature and produces minimal or no carbon emissions. It leverages plastic waste, an abundant environmental pollutant, as a renewable carbon source, effectively turning trash into treasure. As Professor Wallace notes, waste is essentially just carbon, and microbes are adept at processing carbon compounds. This approach offers a way to utilize waste that would otherwise be incinerated or sent to landfills, contributing to a more circular economy.

The research aligns with growing efforts within the pharmaceutical industry and beyond to decarbonize supply chains and adopt more sustainable manufacturing practices. Support for the study from entities like AstraZeneca highlights the commercial interest in exploring such green chemistry solutions.

From Lab Breakthrough to Real-World Impact

While the scientific achievement is significant and demonstrates exciting potential, the researchers emphasize that this technology is still in its early stages. So far, only small quantities of paracetamol have been produced and extracted in the lab.

The next critical steps involve scaling up the process to make it commercially viable. This presents practical challenges, including ensuring a consistent quality and composition of post-consumer plastic waste feedstock, which can vary widely.

Furthermore, any drug produced using this method would need to undergo rigorous safety, purity, and regulatory testing, including extensive human trials, before it could be approved for medical use. This is a lengthy and closely monitored process.

Experts not involved in the study, while praising the scientific ingenuity, also highlight practical considerations regarding scalability and economic competitiveness compared to the current, highly optimized, and inexpensive chemical synthesis methods for paracetamol. Some also caution against viewing such technologies as a silver bullet for the global plastic crisis, emphasizing the fundamental need to reduce plastic production at the source.

Despite the challenges ahead, this research represents a powerful proof-of-concept. It showcases the potential of engineered microbes to act as tiny, efficient chemical factories, capable of upcycling waste materials into valuable compounds, including essential medicines. The success with paracetamol suggests that similar approaches could potentially be developed for producing other pharmaceuticals and chemicals, paving the way for a future where both medicine and materials are made more sustainably, moving away from reliance on fossil fuels.