Probable Cause Identified: Missing Bolts and Systemic Failures

In a significant finding following a months-long investigation, the National Transportation Safety Board (NTSB) has determined that multiple system failures at Boeing, coupled with inadequate oversight by the Federal Aviation Administration (FAA), were the probable cause of a door plug blowing off an Alaska Airlines Boeing 737 Max 9 jet midair. The terrifying incident occurred on January 5, 2024, shortly after Flight 1282 departed from Portland, Oregon.

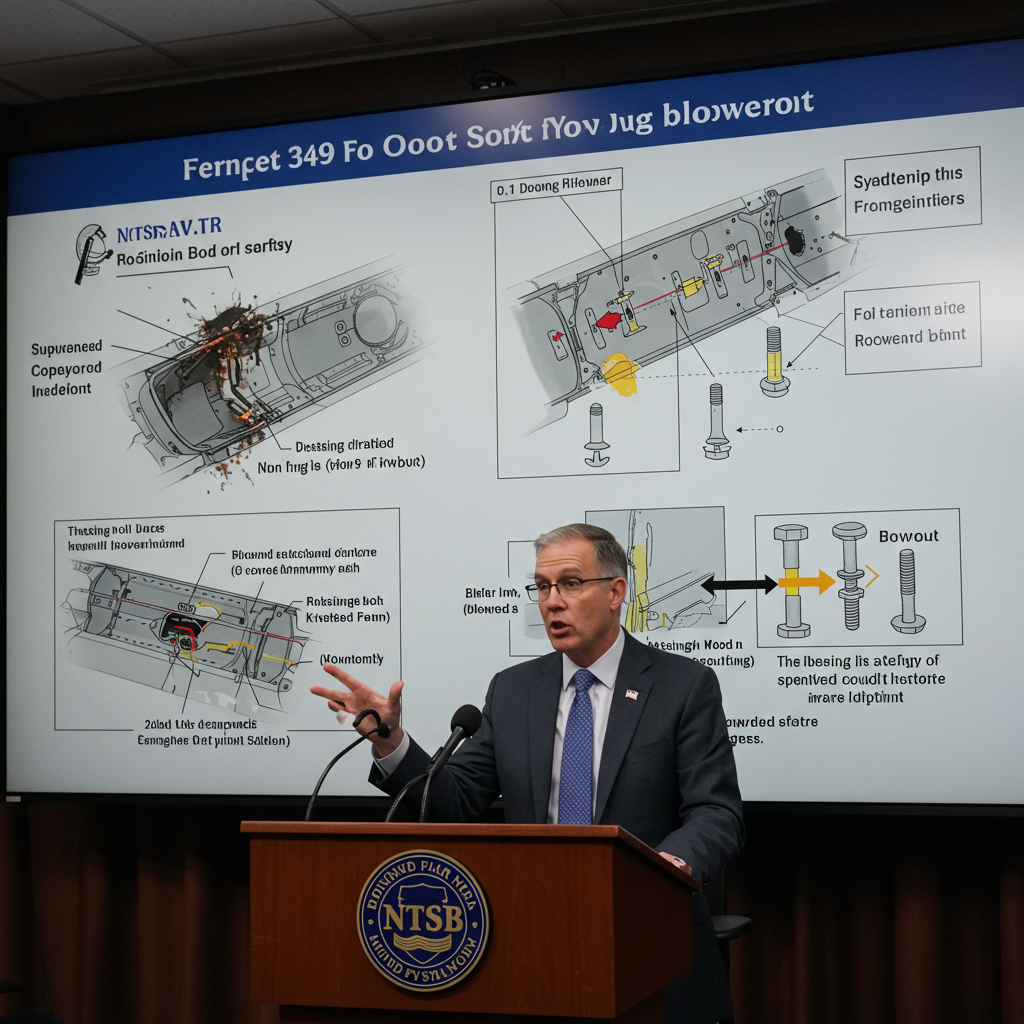

Government investigators revealed that the core issue traced back to the absence of four crucial bolts designed to secure the mid-cabin door plug in place. The NTSB’s 17-month probe concluded that even the presence of just one of these vertical movement arrestor bolts could have prevented the panel from detaching.

Boeing’s Manufacturing Failures Blamed

The investigation pinpointed significant lapses within Boeing’s manufacturing process at its Renton, Washington, factory. Evidence showed the door plug was removed by employees to facilitate a repair of damaged rivets located nearby. Crucially, the four bolts were not reinstalled after this work was completed.

NTSB analysis, including reviewing photos from the factory floor, indicated the plug was closed without the bolts in visible locations, strongly suggesting they were missing before the aircraft was delivered or the incident occurred.

The NTSB highlighted several contributing factors within Boeing:

Lack of Documentation: There was no required paperwork detailing the opening and closing of the door plug during the rivet repair. Boeing later admitted that the documents required by their processes were likely never created.

Untrained Personnel: Investigators found that the team assigned to the specific repair on this aircraft was not adequately trained to remove and reinstall door plugs. Only one individual on the factory’s door team had prior experience with this task, and that person was on vacation when the work was performed.

Inadequate Oversight & Quality Control: Boeing failed to ensure workers consistently and correctly followed established procedures for parts removal and reinstallation. Factory employees reportedly felt pressure to work quickly, potentially compromising safety protocols.

NTSB Chair Jennifer Homendy emphasized that an accident of this magnitude is not due to individual error but results from systemic breakdowns within the manufacturing and quality control systems.

Insufficient FAA Oversight

Beyond Boeing’s manufacturing issues, the NTSB also cited the FAA’s insufficient oversight as a contributing factor. The agency’s inspection system did not effectively catch systemic failures at Boeing. The NTSB found a lack of clear standards for FAA audits of Boeing and noted that past inspection records were routinely discarded, failing to inform future inspection plans.

The Incident and its Aftermath

When the door plug blew out at around 16,000 feet, the sudden rapid decompression caused a loud roar, deployed oxygen masks, and created a vacuum effect that sucked objects, including cellphones and a pilot’s headset, out of the cabin. While seven passengers and one flight attendant sustained minor injuries, the outcome could have been far worse; the NTSB specifically noted the potential danger to lap-sitting children had they been seated closer to the opening.

Investigators credited the heroic actions of the flight crew for safely landing the plane back in Portland, averting a potential disaster. However, the NTSB stressed that the crew should never have been put in such a perilous situation.

Adding context, the NTSB investigation suggested the plug had likely been gradually moving upwards over the aircraft’s 154 prior flights because it was not properly secured. Alaska Airlines had also, unrelatedly, restricted this specific plane to overland flights before the incident, which NTSB members noted likely helped mitigate the severity of the outcome compared to being over water.

Recommendations for Improved Aviation Safety

Based on its findings, the NTSB issued nearly two dozen safety recommendations aimed at preventing similar incidents. Key recommendations include:

For Boeing: Significantly improve training, quality control processes, documentation practices, and ensure safety plans and procedures are understood and implemented throughout the company, not just at the executive level. Better identify and manage manufacturing risks.

For the FAA: Improve audits and inspections of manufacturers like Boeing, focusing on systemic issues and using past findings to inform future oversight. Assess manufacturers’ safety culture.

For Boeing, Spirit AeroSystems (which made the plug), and the FAA: Work to ensure all 737 Max planes equipped with door plugs are retrofitted with a redesigned panel featuring backup systems to prevent detachment, though certification for this fix is not expected until 2026 at the earliest.

Both Boeing and the FAA have responded to the NTSB report, stating they are reviewing the findings and implementing changes. The FAA has acknowledged it has fundamentally changed its oversight of Boeing since the accident and is maintaining “aggressive oversight,” including a production cap on new 737 aircraft until quality issues are fully addressed. Boeing has stated it is working to strengthen its safety and quality operations and is cooperating with ongoing investigations, including a criminal probe reportedly launched by the Department of Justice.