Turning Plastic Waste into Painkillers: A Scientific Breakthrough

Plastic pollution is a global crisis, overwhelming landfills and ecosystems. Meanwhile, many essential products, including common medicines like paracetamol, rely on fossil fuels for their production. What if there was a way to address both problems simultaneously? Scientists are now exploring just that, using engineered bacteria to convert plastic waste into the active ingredient in paracetamol.

In a groundbreaking study published in the journal Nature Chemistry, researchers at the University of Edinburgh demonstrated a novel process that merges chemistry and biology. Their work shows how polyethylene terephthalate (PET) plastic – the type commonly found in plastic bottles and food packaging – can be transformed into paracetamol (also known as acetaminophen) using genetically modified E. coli bacteria.

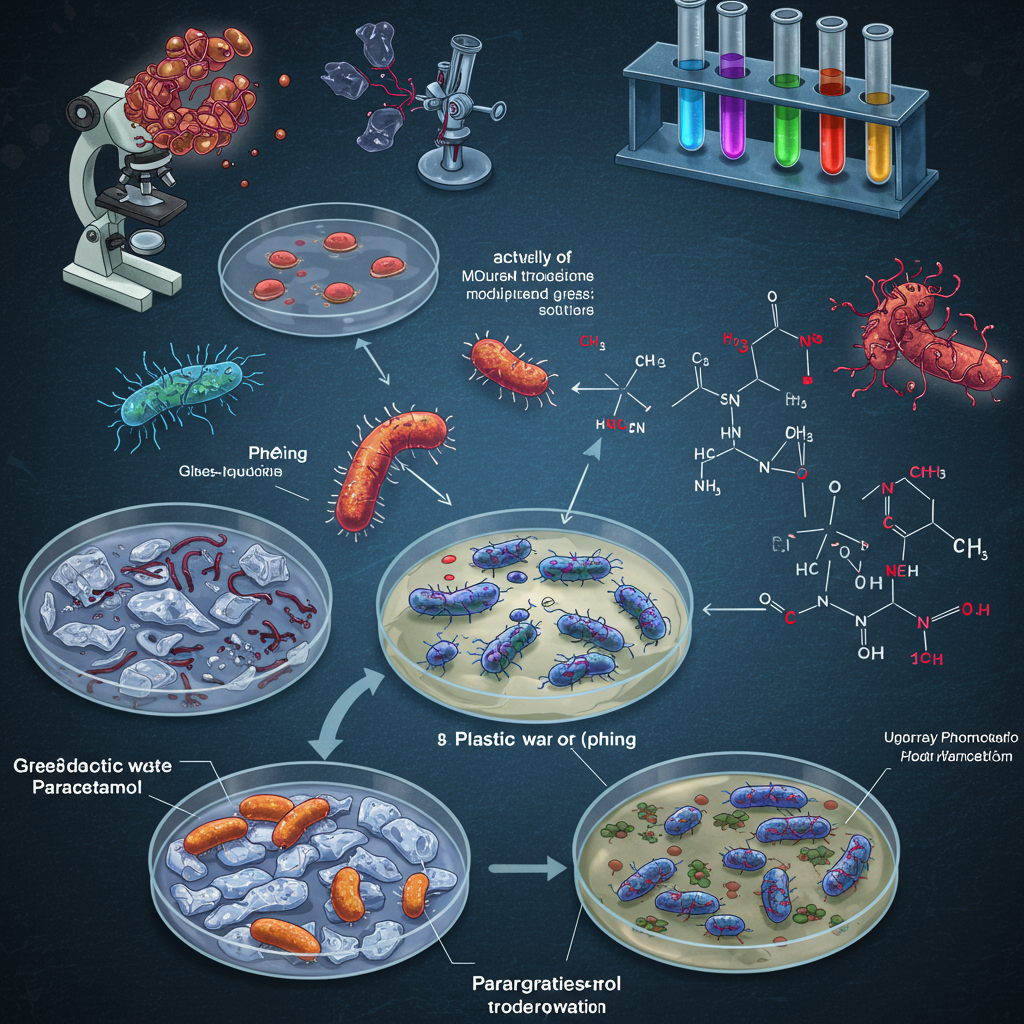

The Hybrid Chemistry-Biology Process

Current methods for producing paracetamol typically start from oil-derived chemicals. This new approach offers a potentially more sustainable alternative. The team’s method involves a two-step process:

- Chemical Pre-treatment: PET plastic is first subjected to sustainable chemical methods to convert it into an intermediate molecule.

- Bacterial Transformation: This intermediate molecule is then introduced to specially engineered E. coli bacteria.

A key discovery was that a specific type of chemical reaction, a Lossen rearrangement, which is usually performed under harsh laboratory conditions and had never been observed in nature, could occur spontaneously within the living E. coli cells. The scientists found that phosphate within the bacteria helped catalyze this reaction.

This initial bacterial process converts the plastic-derived molecule into PABA (para-aminobenzoic acid). PABA is a substance naturally required by bacteria for growth and DNA synthesis. However, the E. coli strain used in the experiment was genetically modified to block its natural PABA synthesis pathways, essentially forcing it to consume the plastic-derived material as its food source.

Building on this, the researchers further modified the bacteria by inserting genes from other organisms – one from mushrooms and one from soil bacteria. These genes enabled the E. coli to perform the crucial final step: converting the PABA directly into paracetamol.

Promising Efficiency and Potential

The results are highly encouraging. The team reported that this hybrid process was capable of converting the plastic-based starting material into paracetamol with remarkable efficiency, achieving a yield of up to 92% in under 24 hours.

Professor Stephen Wallace, the lead author of the research, highlighted the significance: “People don’t realise that paracetamol comes from oil currently,” he said. “What this technology shows is that by merging chemistry and biology in this way for the first time, we can make paracetamol more sustainably and clean up plastic waste from the environment at the same time.” He added that this process provides a new way to “hoover up plastic waste” and give it value.

This approach offers a valuable “dual benefit”: reducing reliance on fossil fuels for drug production and providing a method to “upcycle” waste plastic into a valuable commodity, contributing to a more circular economy.

Challenges and Future Outlook

While the findings are exciting and represent a significant scientific step – demonstrating a pathway from plastic waste to paracetamol that couldn’t be achieved by either chemistry or biology alone – the technology is currently at the laboratory stage. Scaling this process up for commercial-level production presents practical challenges.

Experts not involved in the study note that further development is needed to optimize the initial chemical reaction’s yield and standardize the overall process before it can be widely implemented. Furthermore, some commentators suggest that while innovative waste management solutions are important, the primary focus for tackling plastic pollution should remain on reducing the production and consumption of plastic in the first place.

Despite these hurdles, this research showcases the immense potential at the intersection of chemistry and biology to address major global challenges. It offers a glimpse into a future where waste materials could become feedstocks for essential goods, creating a cleaner and more sustainable path for industries like pharmaceuticals. Further work is needed to bring this promising technology from the lab to industrial scale, but the potential to transform plastic waste into valuable medicines is now a tangible possibility.